GET 20% OFF YOUR FIRST ORDER. USE CODE: "FIRST20"

Glass vs Aluminium vs Boxed - Which Water is Best?

June 21, 2021

With the world back pedalling on plastic production, the race to find a replacement for drinks receptacles is heating up. At present, there are few options that present a stronger case than aluminium. Although the initial impact from its production is tough on the earth’s resources, its reuse and recyclability make it a front runner in the race.

But What Else Might be Considered?

Long before plastic and aluminium were even dreamt of for production, we relied on glass. Made up of liquified sand, soda ash and limestone, glass production results in mining, emissions of gasses and transport costs. These figures, much like with aluminium, can be offset by recycling and reusing the material.

As a receptacle glass provides many benefits. Many people prefer to drink beverages from glass receptacles claiming the glass holds a fresher, crisper taste. Whilst this may be true, the reality of glass bottles is that at many venues or events, the requirement is to transfer your drink into **horror music intensifies** a plastic cup.

The glass bottles heavy and brittle nature creates a conundrum for many. When broken, glass presents a danger. Broken glass is much more likely to be discarded into regular waste than become part of the recycling carousel.

For waste management and recycling centres, coloured glass needs to be separated into individual colours. Recycling different hues of glass together will diminish the quality of the recycled glass. The effort needed to create a like-new quality glass cullet isn’t always economically viable.

Another downside to glass that needs consideration is its transport. As we learned, glass is heavy and brittle. This means the weight requires much more fuel to transport it. Couple this with the extra care in packaging the bottles to reduce the risk of damage, and you have a considerable difference when compared to lightweight, aluminium cans.

Research published by www.euronews.com shows the difference in energy savings when recycling both glass and aluminium.

Recycling glass: -

- 42 kilowatt hours of energy

- 19 litres of oil

- 54 ft3 of landfill space

Recycling aluminium: -

- 14,000 kilowatt hours of energy

- 6,545 litres of oil

- 270 ft3 of landfill space

Due to its highly recyclable nature, it is much more likely that the can you’re drinking from will be made of recycled aluminium. The process by which aluminium is made takes much more energy than recycling used material. Hence the reason many aluminium manufacturers push so heavily to have the used products returned to them.

Other Options

Lately, we’ve seen a new trend in the market. Boxed water is becoming more and more popular. Boxed water trumps plastic and glass on eco-friendliness, especially on transport. Flat packed and stacked you’ll fit many, many more containers on a lorry than you would a rigid receptacle. Once they arrive at the ‘bottling’ source they can be filled and then shipped out.

The issue presented by cartons, is the coating. Cartons are usually around 75% paper, but still reliant on a polyethylene/plastic coating for waterproofing. Very few recycling outfits will separate the two, leaving the carton to go to landfill. The result is a single use container.

Trees may be replaced, but the end of line for the carton is often the ground, with only 75% being biodegradable. And so the reliance on plastic coating serves as its downfall, to this otherwise eco-friendly product.

Conclusion

As clean and clear as glass may seem, and as flat packed as boxes may arrive to the source. With recycling figures taken into account, aluminium pips glass and cartons to the post to take poll position in the quest for a greener, more viable vessel for beverages.

To find out more about the benefits of aluminium, click here.

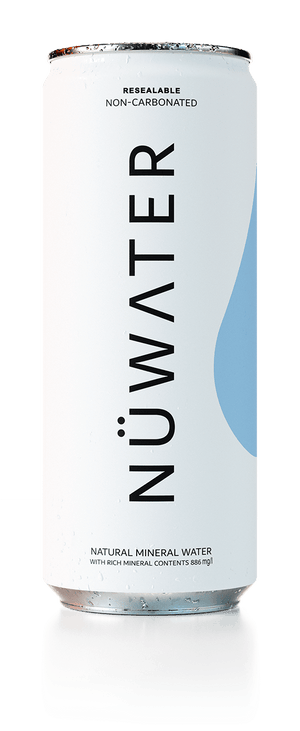

Visit our website to choose from our nutrient-rich mineral water, guilt-free in a resealable aluminium can.

Leave a comment

Comments will be approved before showing up.